Murray State University in Kentucky has played a key role in developing a new patented plastics recycling technology that could revolutionize the plastic recycling industry. The university’s Center for Sustainable Energy Research (CSER) partnered with UK-based company Impact Solutions to create this groundbreaking technology.

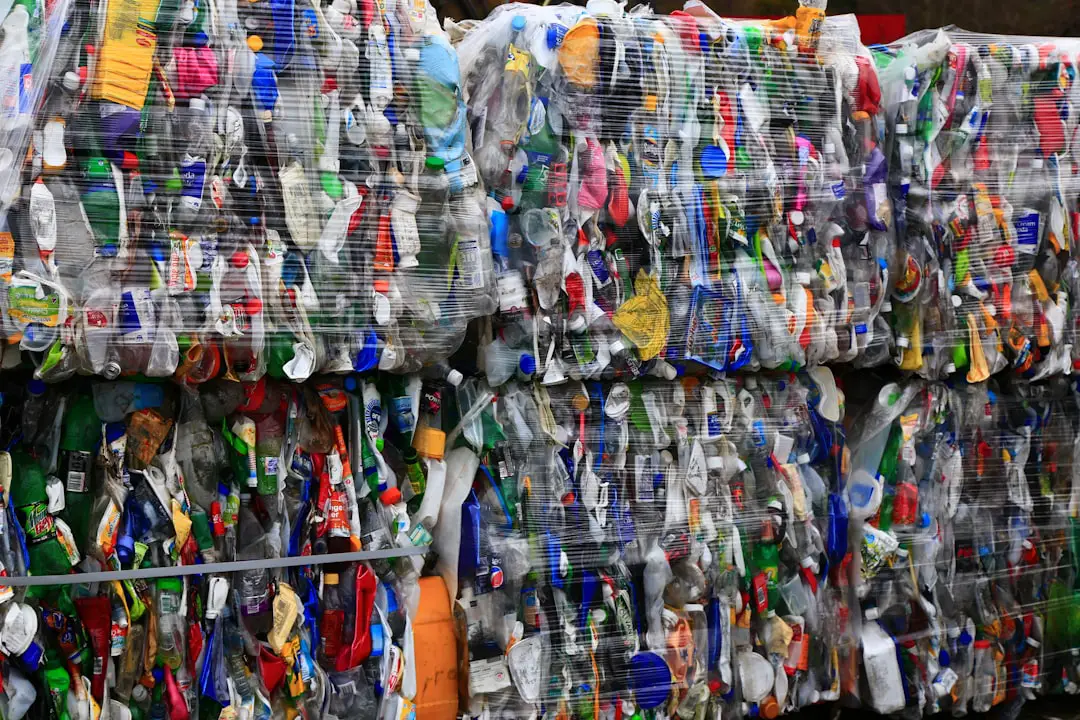

The new technology, called PolyMET, is a method for recycling plastics that are typically difficult to recycle, such as mixed plastics and contaminated plastics. PolyMET uses a chemical process to break down the plastics into their basic building blocks, which can then be used to create new plastic products. This innovative approach not only reduces waste but also helps to conserve resources by reusing existing plastic materials.

Dr. Wei-Ping Pan, director of CSER, expressed his excitement about the potential impact of PolyMET on the plastics recycling industry. He noted that traditional methods of recycling plastics often involve downcycling, where the quality of the plastic is degraded with each recycling cycle. PolyMET, on the other hand, allows for the creation of high-quality recycled plastics that can be used for a wide range of applications.

The development of PolyMET is a significant achievement for both Murray State University and Impact Solutions. It not only showcases the innovative research being conducted at the university but also highlights the potential for collaboration between academia and industry to drive technological advancements.

As the world grapples with the challenges of plastic pollution and waste management, technologies like PolyMET offer a ray of hope for a more sustainable future. With continued research and development, it is possible that PolyMET and similar technologies could help to address the global plastic waste crisis and create a more circular economy for plastics.

Source: Lane Report